Perfect disinfection throughout the entire hatchery

Case

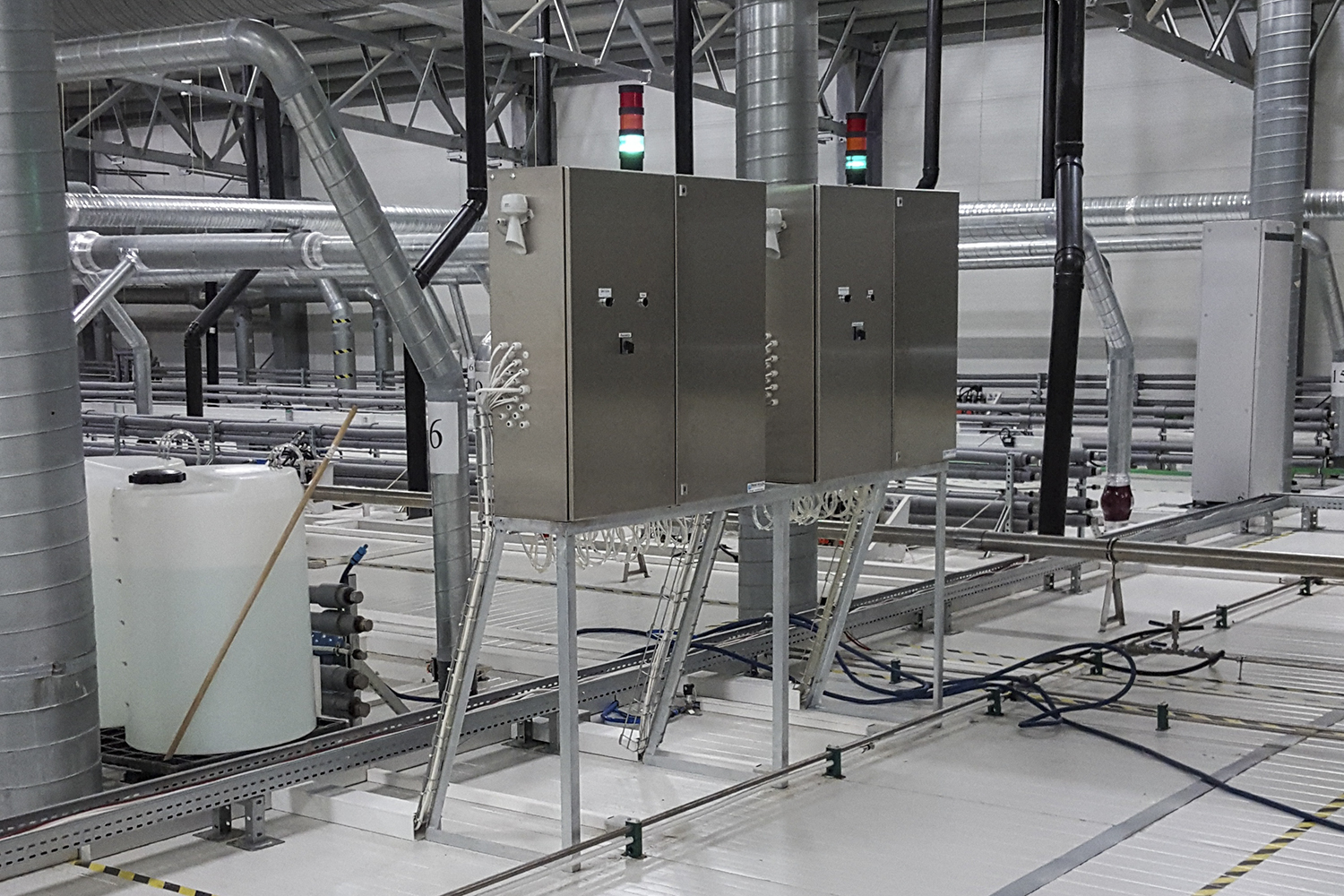

Just a few years ago, a hyper modern hatchery at the German-Polish border was opened. To obtain widespread periodic disinfection at the hatchery, Veugen Technology set up a total of 48 nozzles in the hatchers (30) and production areas (18). Together, they form the Halofog800 system.

The entire company is disinfected on set times, to prevent harmful substances infecting the eggs. From a central point, equipped with timers, the disinfection agent is sent to all nozzles. Some areas where nozzles are placed include the washing area, inspection area and meeting room.

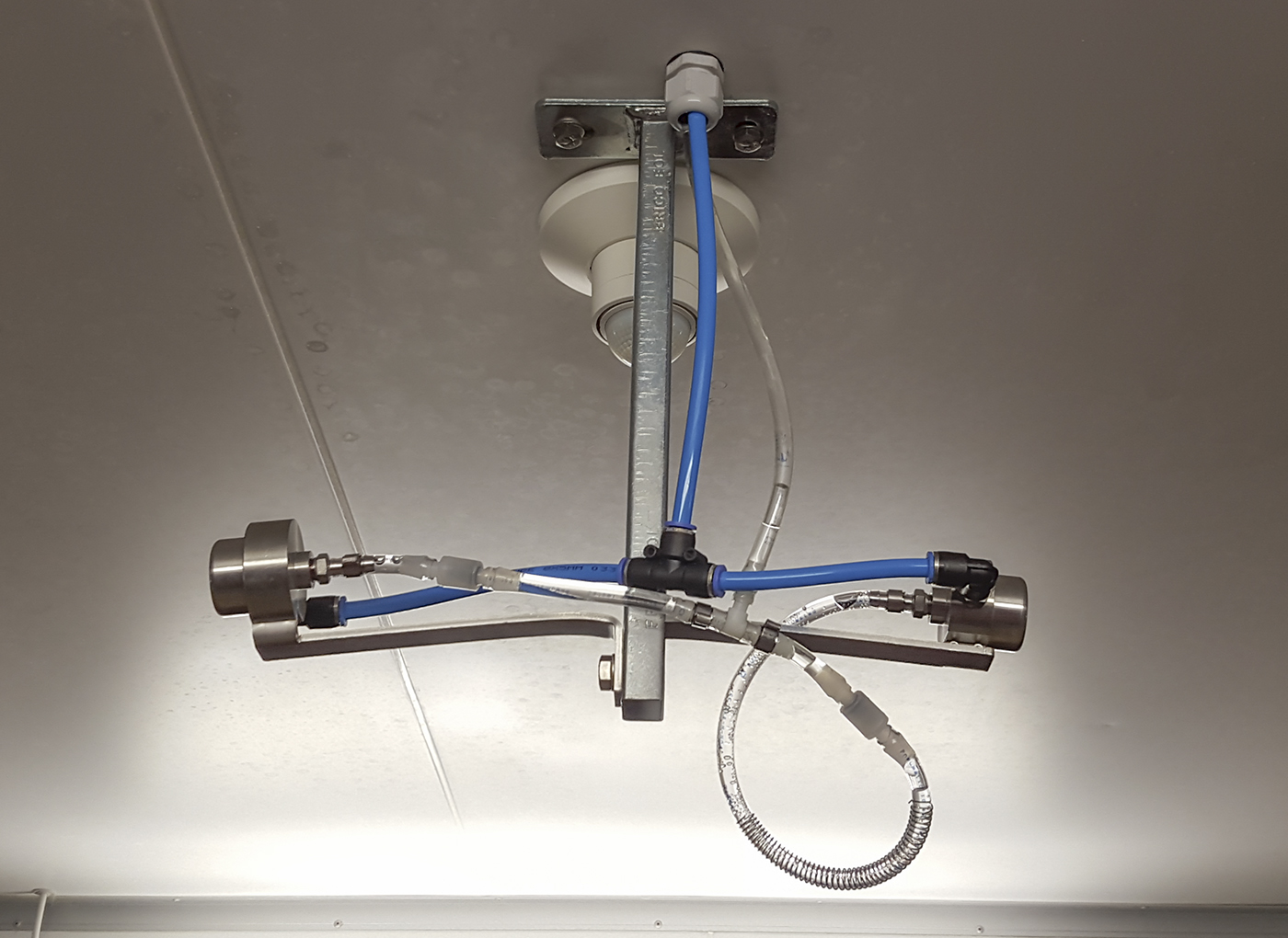

We used special satellite nozzles for this project. The advantage of these are that they are placed at the back end of a beam. When the nozzle starts spraying the beam shakes a little and this allows for the mist to be even finer.

company profile

Hatchery

Poland

Largest hatchery of the country

Foggers

48 nozzles, attached to the Halofog800 system.

BENEFITS OF EGG DISINFECTION

Click here for de benefits of egg disinfection.